A skilled clockmaker was able to make around six to ten clocks per year, with a clock costing around €400–900 in nowadays prices. It was a luxury piece affordable only to the wealthiest, and custom made on order. Even then, the components for clocks were painstakingly filed by hand, and fitted together with even more frequent adjustments and filing.

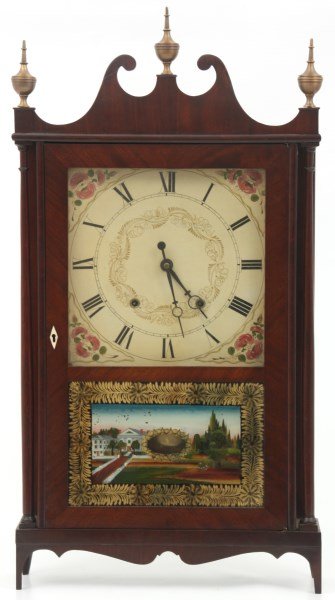

Since metal was rather expensive back then, many clocks were mostly made of wood, and only crucial parts were made of metal. Clockmakers in America started making clocks from the 18th century onward.

A clock at home was affordable only to the rich. Clocks on church towers and other public buildings were sort of a service to the public so everybody could check the time. But these required effort and often were quite expensive. From the sun (or its shadow) to water clocks, marks on candles, hourglasses with sands, to mechanical gears. Measuring time has always been of interest to humanity. On Clocks… The largest church clock in Europe is in Zürich Hence I will go back in history to look at his life. His name is known mostly to nerds in manufacturing and horology, but I believe his achievements deserve recognition. 1785), and long before John Hancock Hall at the Harpers Ferry Armory (ca. He was one of the earliest industrialists using mass production with interchangeable parts in the USA, contemporary with the better-known muskets of Honoré Blanc in France (ca. Two hundred fifty years ago today, clockmaker Eli Terry was born on Apin (what is now) South Windsor, Connecticut, USA.

0 kommentar(er)

0 kommentar(er)